Order Orchestration

The effective optimisation of order fulfilment processes

Order Orchestration is the process that enables organisations to efficiently manage and fulfil customer orders. With complete inventory visibility, order orchestration selects the best stock location – whether internal or a supplier – to manage each order through to delivery, while ensuring that business requirements and customer expectations (the famous delivery promise) are met or exceeded.

Key benefits of OneStock’s Order Orchestration

Configurable and agile

OneStock Order Orchestration offers effortless adaptability to dynamic business requirements, allowing order processing rules to be easily updated in the back office – even by non-technical users – just by dragging and dropping rules in the preferred order, ensuring flexibility and efficient response to changing conditions.

Competitive order allocation

This allocation model gives businesses the ability to send the same order to multiple fulfilment locations, where the first to claim the order fulfils it. This process is inspired by big tech companies like Uber and has numerous advantages, but the main one is that the order is allocated to a location that is really motivated to fulfil it – accelerating the overall time to customer.

Sustainable order fulfilment

With intelligent algorithms selecting the optimal delivery route, minimising splits, aggregating orders and reducing the need for reactive shipments from warehouse to stores, Order Orchestration helps to reduce carbon footprints, align with green practices and support sustainability.

Why Orchestration creates a real competitive advantage

Better logistics operations

Orchestration involves routing capabilities to manage inventory between stores, warehouses, suppliers, resellers and third-party logistics providers. Efficient coordination with these partners helps create a seamless supply chain, improving overall efficiency and reducing delays for customers.

Omnichannel sales support

For organisations operating through multiple sales channels, Orchestration ensures that all orders are managed efficiently by finding the stock and the optimal fulfilment location to avoid order cancellations.

Increased agility and adaptability

Brands will always face seasonal demands, changing market conditions and unexpected events. Orchestration enables them to be agile and adapt quickly to these changes, ensuring they can meet customer needs.

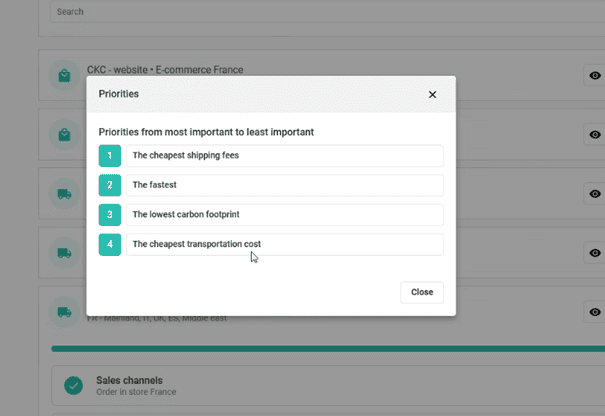

OneStock provides its users with highly customisable configuration rules through intelligent workflows, based on business objectives and processed in real time, that can consider: geographic proximity, transport costs and delays, number of packages and shipping points, stock levels, store traffic and more. They can even create their own custom rules to adapt order routing to their specific business needs.

How does Order Routing work?

Let’s explain it through an example:

1

A customer places an online order containing two different products.

2

The brand has configured its orchestration rules to prioritise the warehouse for online order fulfilment, so that OneStock’s algorithms analyse the availability of these items across all warehouses. One of the products is no longer available in the central warehouse but is still available in various stores.

3

Instead of sending the order in two separate shipments, OneStock OMS follows the brand’s next orchestration rule and intelligently identifies the most optimal fulfilment location to send the order in a single package. This store has both products in stock and is geographically closest to the customer’s delivery address.

4

The OMS generates a return confirmation via email or through the customer portal.