3PL Meaning Uncovered: A Comprehensive Guide to Third-Party Logistics

In today’s rapidly evolving business landscape, efficient supply chain management is the key to competitiveness, profitability and sustainability. This is where third-party logistics (3PL) comes into play. But what exactly does it mean, and how can it benefit your business?

In this comprehensive guide, we’ll delve into the depths of 3PL, exploring its core definition, the diverse services available, the advantages it offers, tips for selecting the right provider, emerging trends, and optimisation strategies.

By the end, you’ll have a clear understanding of 3PL and how it can be a game-changer for your logistics operations.

What’s the meaning of 3PL? A definition

To begin our journey into the world of 3PL, let’s start with the basics.

Basic understanding

3PL, or third-party logistics, is the outsourcing of logistics and supply chain management functions to an external provider. These providers offer services such as transportation, warehousing, inventory management, order fulfilment and distribution. Leveraging the expertise and resources of a specialised 3PL provider allows businesses to streamline operations, improve efficiency and reduce costs, while focusing on their core competencies.

Role in supply chain management

3PL providers play a crucial role in the broader supply chain ecosystem. They act as intermediaries between manufacturers, suppliers, stores, wholesalers and customers, ensuring smooth coordination and execution of logistics activities. Overall, 3PLs play a vital role in optimising supply chain processes and ensuring the timely and efficient movement of goods from point of origin to point of consumption.

Varieties of 3PL services

When it comes to 3PL, one size does not fit all. A range of services are available to address the unique needs of businesses:

Transportation providers

Transportation is a cornerstone of the supply chain, and 3PL transportation providers excel in the efficient movement of goods from point A to point B. They handle route optimisation, carrier selection and shipment tracking, ensuring that stock and orders are delivered on time and in good condition.

Warehouse and distribution providers

For businesses with complex inventory and order management needs, warehouse and distribution 3PL providers are indispensable. They handle the receipt, inspection, storage and tracking of inventory, as well as the efficient and accurate picking, packing and shipping of products to points of sale or directly to consumers.

Full-service providers

Some 3PL providers offer end-to-end solutions for businesses looking to outsource their entire supply chain. Full-service providers have a comprehensive suite of services that encompass transportation, warehousing, order fulfilment, returns management, and value-added services such as kitting, packaging, or product assembly.

Why use 3PL? The advantages

The benefits of using 3PL providers are compelling and far-reaching, touching on various aspects of operational excellence.

Cost savings

One of the biggest benefits of partnering with a 3PL provider is a reduction in costs. By tapping into their expertise, infrastructure and economies of scale, businesses can significantly reduce their labour, warehousing and transportation costs. This also minimises the need for costly investments in warehouse space, technology and equipment.

Expertise and focus

Logistics is a complex and ever-evolving field. 3PL providers are specialists in their domain, staying up to date with the latest industry trends, regulations and best practices to ensure they deliver the best possible service to their clients. By partnering with them, businesses can tap into this expertise and free up their internal teams to focus on core competencies.

Scalability and flexibility

In a dynamic commerce environment, your logistics needs will fluctuate with market conditions and business growth. 3PL providers offer both flexibility and scalability, allowing companies to adapt swiftly to shifts in demand. This agility is particularly valuable for businesses seeking to maintain competitiveness, meet customer expectations and accelerate business expansion.

How to choose a 3PL provider

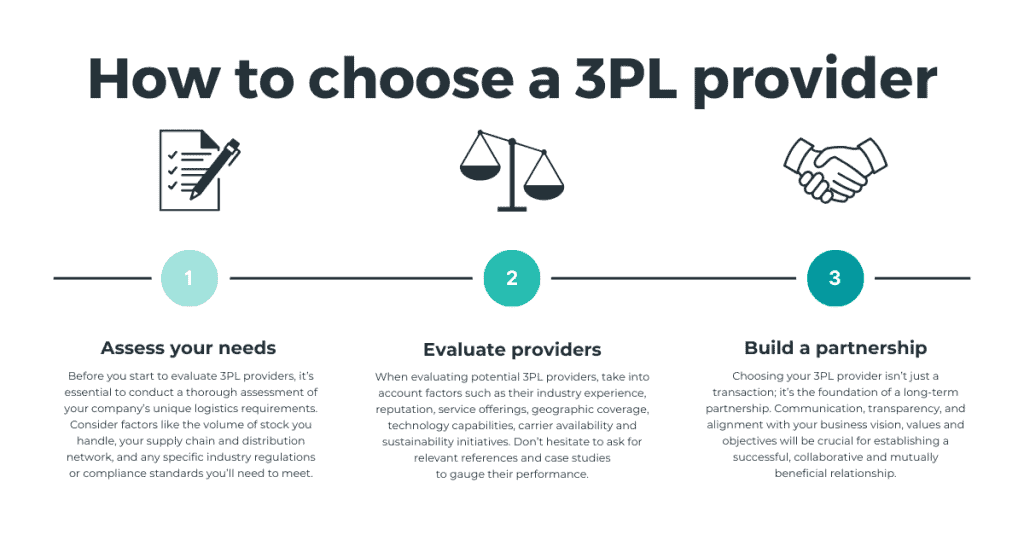

Selecting the right 3PL provider for your business is a critical decision that can significantly impact your supply chain efficiency. Here’s our step-by-step guide to help you make an informed choice:

Assessing your needs

Before you start to evaluate 3PL providers, it’s essential to conduct a thorough assessment of your company’s unique logistics requirements. Consider factors like the volume of stock you handle, your supply chain and distribution network, and any specific industry regulations or compliance standards you’ll need to meet.

Evaluating providers

When evaluating potential 3PL providers, take into account factors such as their industry experience, reputation, service offerings, geographic coverage, technology capabilities, carrier availability and sustainability initiatives. Don’t hesitate to ask for relevant references and case studies to gauge their performance.

Building a partnership

Choosing your 3PL provider isn’t just a transaction; it’s the foundation of a long-term partnership. Communication, transparency, and alignment with your business vision, values and objectives will be crucial for establishing a successful, collaborative and mutually beneficial relationship.

The future of 3PL: trends to watch

As technology continues to reshape the logistics landscape, several trends are emerging that are poised to shape the future of 3PL. Here are two key areas to keep a watchful eye on:

Technological innovations

Automation, artificial intelligence, and data analytics are transforming how 3PL providers operate. These technologies are driving improvements in route optimisation, inventory management and real-time tracking, making logistics processes even more efficient and cost-effective.

Environmental considerations

The logistics and transport sector is the largest emitter of carbon emissions globally and it is becoming increasingly important for businesses to address the environmental impact of their supply chains. Many 3PL providers are adopting more sustainable practices, such as optimising transportation routes to reduce carbon emissions and implementing green warehousing solutions. As environmental regulations and consumer expectations evolve, this trend is set to gain momentum.

Optimisation in 3PL: a closer look

Optimising your 3PL operations is crucial for unlocking the full potential of outsourcing, and there are three key areas where optimisation plays a significant role:

Streamlining processes

Efficiency is at the heart of logistics optimisation. 3PL providers employ various strategies to streamline processes, with effective inventory management and continuous improvement initiatives resulting in reduced costs, faster order fulfilment and happier customers.

Enhancing communication and collaboration

Effective communication and collaboration between your business and your 3PL provider are essential for success. Integration of systems, real-time data sharing and clear communication channels ensure that everyone is on the same page and can respond quickly to changes or issues.

Measuring performance

Regularly measuring and analysing key performance indicators (KPIs) is vital for 3PL optimisation. Metrics like on-time delivery rates, inventory turnover and order accuracy can help identify areas for improvement and ensure that your 3PL provider is meeting expectations and SLAs.

Real-world examples: 3PL in action

To illustrate the tangible benefits of 3PL, let’s delve into some real-world case studies and best practices:

Case studies

ManoMano: Europe’s leading online retailer for home improvement has partnered with 3PL providers in France and Spain to offer deliveries in 24 and 48 hours, which has contributed to a 35% increase in customer satisfaction. Read more >

Webedia: The leading digital entertainment group uses a 3PL provider to manage stock and orders across its own e-commerce sites and marketplaces like Amazon, while providing customers with a reliable, accurate Delivery Promise. Read more >

Best practices

Collaborative planning: Your 3PL provider is an expert in what they do. Foster a collaborative relationship by involving them in strategic planning and decision-making.

Continuous improvement: Encourage a culture of continuous improvement to drive efficiency and cost savings in your logistics operations – a win-win for both parties.

Data sharing: Share relevant data with your 3PL partner, such as order cancellation rates and reasons, to enable better decision-making and optimisation opportunities.

Summary and next steps: embracing 3PL

We’ve journeyed through the world of 3PL, uncovering the fundamental meaning, its pivotal role in supply chain management, the diverse services available and the multitude of benefits it offers businesses.

As we draw this comprehensive guide to a close, let’s consider the key takeaways and chart a course for embracing 3PL successfully.

Recap of 3PL meaning

Third-party logistics (3PL) is a powerful strategy for the optimisation of your supply chain. By outsourcing various logistics functions to specialised providers, you can enjoy operational efficiencies, cost savings, expertise, flexibility and scalability.

Practical tips for implementation

Implementing a 3PL strategy requires careful planning and execution. Here are our tips to help you get started:

1. Assess your needs thoroughly

Before engaging with 3PL providers, conduct a detailed analysis of your logistics requirements. Consider factors like stock and order volumes, geographic reach and industry-specific compliance. This assessment will guide your selection process.

2. Choose the right provider

Selecting the appropriate 3PL provider for your business is critical. Evaluate potential partners based on their experience, reputation, services and technology capabilities. Remember that compatibility in vision and values is equally important for a successful partnership.

3. Establish clear communication

Open and transparent communication with your 3PL provider is essential. Create clear channels for sharing information and addressing issues promptly. Integration of systems and data sharing can streamline operations.

4. Measure and analyse performance

Regularly monitor key performance indicators (KPIs) to ensure that your 3PL provider is meeting expectations and SLAs, and use data-driven insights to identify areas for improvement and optimisation.

5. Embrace technology

Leverage technology solutions offered by your 3PL partner. Automation, real-time tracking and data analytics can enhance efficiency and visibility in your supply chain.

6. Foster a collaborative culture

Build a collaborative relationship with your 3PL provider. Involve them in strategic planning and decision-making processes to align your goals and drive mutual success.

Continuing education and resources

To stay updated on the latest trends, best practices and advancements in the world of logistics, explore these valuable resources:

Recommended reading

- OMS: The mastermind behind your logistics and transport operations

- What is an Order Management System (OMS)?

- Order Management System vs. Warehouse Management System: What are the main differences?

Industry publications

- OneStock blog: As the European leader in distributed order management, we offer best practices for supply chain optimisation and commentary on the latest news, trends and technology advancements for omnichannel commerce.

- Logistics Manager: The leading monthly magazine for managers in charge of the supply chain for the UK’s largest industrial, retail and commercial organisations.

- DeliveryX: A trade title for professionals in supply chain, operations, logistics, warehousing, customer support and related services, to support multichannel retail.

Now that we’ve thoroughly uncovered the meaning of 3PL, its benefits and optimisation strategies, you’re well on your way to harnessing the power of third-party logistics to enhance efficiency, reduce costs and remain agile in an ever-evolving omnichannel environment.